How can e-NG decarbonize the shipping industry?

January 3, 2024

Reading time: 5 min

Maritime transport contributes to about 3% of global greenhouse gas emissions (GHG) and is a significant source of air pollution. Without intervention, these emissions could increase by 250% by 2050.

Long-distance ships require high-energy fuels as they must travel thousands of miles before refueling. Currently, most ships run on various petroleum products like heavy fuel oil (HFO) marine gas oil (MGO), and marine diesel oil (MDO). These noxious fuels release carbon dioxide as well as harmful sulfur oxides (SOx) and nitrogen oxides (NOx).

With an eye on net-zero goals, shipping companies are actively seeking lower-emission fuel mixes to run their fleets. Switching to liquid or gas biofuels like bio-methanol would already reduce emissions by 60-95%. Biogenic emissions are not usually considered or reported as biofuel combustion is considered carbon neutral. This is because emissions released from biofuels are balanced by carbon that has been sequestered earlier in the process.

Many companies in the shipping industry want to further decrease their carbon profile. Similar to burning biofuels, the emissions released from e-NG combustion are offset by carbon captured and recycled during its production. With onboard carbon capture or an oxy-fuel combustion engine, emissions can be recaptured as they’re emitted.

What are the current laws on GHGs in shipping?

The shipping industry operates worldwide so pollution and emissions from ships are controlled differently in different places. This includes local laws for individual countries and their waters, regional regulations from groups like the European Union (EU), and global rules set by the International Maritime Organization (IMO) which are enforced by each country's own authorities.

Countries can set their own rules for emissions from ships in their coastal waters which is usually defined as the water within 12 nautical miles of their coastline. The IMO aims to reduce the average carbon emissions across international shipping by at least 40% by 2030, and aims to reach 70% by 2050, compared to 2008 levels.

The EU has its own goals under the 'Fit for 55' plan and the related FuelEU Maritime Initiative. These cover all emissions from ships that visit EU ports, including half of the emissions from journeys that start or end outside the EU.

As strict regulations on greenhouse gasses (GHG) begin to emerge, the shipping industry needs to consider alternative fuels with lower carbon emissions, like TES’s e-NG.

How does e-NG compare to other marine fuels?

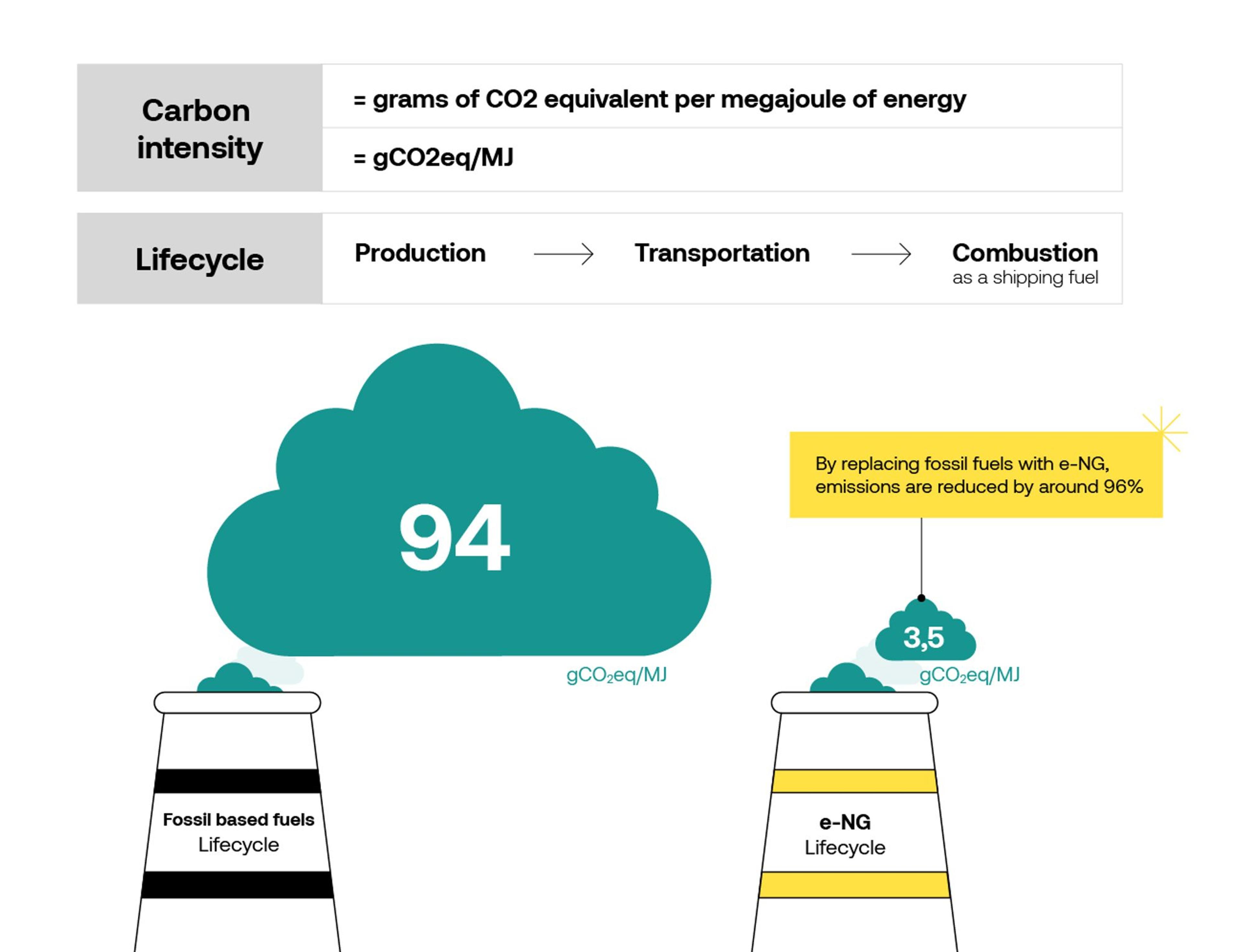

We conducted a Life Cycle Assessment at our e-NG production facility in South West Texas to demonstrate e-NG's feasibility in the shipping industry. A Life Cycle Assessment evaluates greenhouse gas (GHG) emissions from the initial production of fuel to its final use in ships, offering a comprehensive view of a fuel's total emissions.

We assessed carbon emissions and capture at every stage of e-NG production at our South West Texas facility, from production to transportation through to its ultimate combustion as shipping fuel. Our findings revealed that e-NG's entire life cycle has a net positive climate change potential of about 3.5 grams of CO2 equivalent per megajoule (gCO2eq/MJ).

This is compared to the life cycle of fossil-based fuels which emit around 94 grams of CO2 equivalent per megajoule. By replacing fossil fuels with e-NG that has been produced using biogenic CO2, emissions are reduced by around 96%.

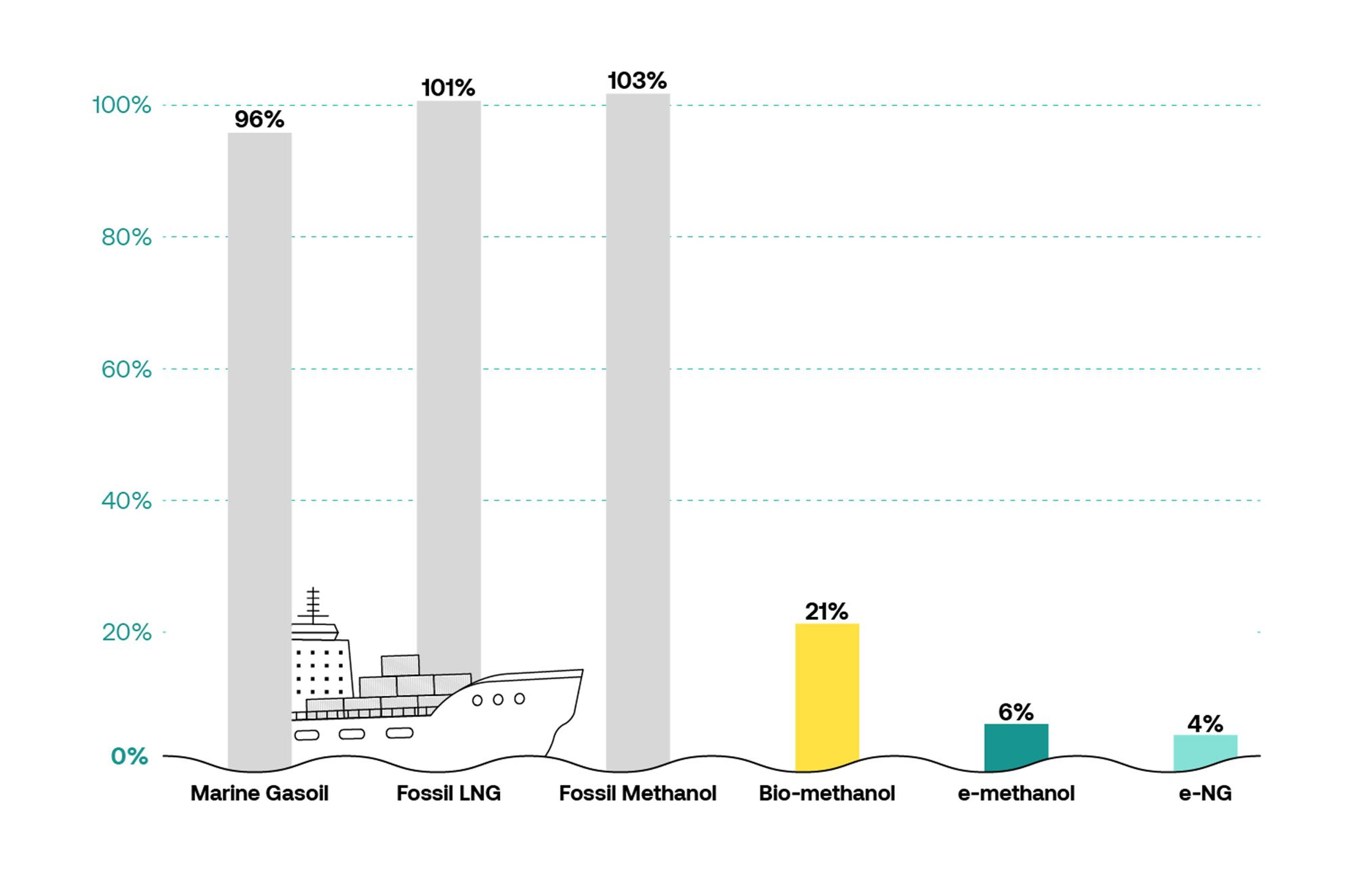

Below, you can see how e-NG compares to other marine fuel alternatives based on data provided in a 2014 paper by Selma Brynolf. It’s important to note that different fuels, depending on their production process, may have different ranges in carbon intensity.

Benefits of e-NG as a marine fuel

As regulations on greenhouse gasses (GHGs) in the maritime and shipping industry tighten, it's crucial for those in the field to explore alternative fuels. A high percentage of the companies that are already diversifying their fuel mix are choosing LNG. e-NG is a far more compelling choice, more economic to produce, and technologically ready for rollout.

As our life cycle analysis demonstrates, e-NG’s production-to-use cycle has significantly lower carbon emissions compared to any fossil-based fuel. Implementing e-NG can also help shipping companies to optimize OPEX (operating expenses).

Ships that currently run on LNG can switch directly to e-NG without needing to update current infrastructure or wait for new technological developments. This means the life cycles of LNG ships are prolonged as e-NG can be used as a drop-in fuel for shipping companies that are gradually moving toward voluntary and regulatory emission reduction targets.

e-NG is a secure, non-toxic molecule that staff already know how to implement. It’s safe for use in passenger as well as cargo ships, and allows ships to enter harbors where ammonia-fuelled ships are often denied entry.

e-NG supply is secure and even in the unlikely event of a molecule delivery shortage, there is no risk of a service disruption as ships could use LNG as a fallback fuel. It also solves the scalability and scatteredness challenges faced by customers of bio-LNG.

e-NG can also be produced on a large scale and supplied globally so it avoids the scattered nature of bio-LNG and is perfectly positioned to become a key solution for rapidly reducing emissions within the shipping industry and the global energy system alike.